Ducting Smoke

Smoke from most Concept systems can be ducted if required, using the inherent velocity of smoke produced by the systems, or incorporating fan assistance if rapid distribution of smoke is required.

Concept has considerable expertise in the application of ducted smoke, as calculating the pressure and flow performance of a proposed ducted system is critical in ensuring an effective result. Every application is different, however, and the pressure required to overcome frictional resistances within the ducting system, and hence the fan specification, depends on many criteria.

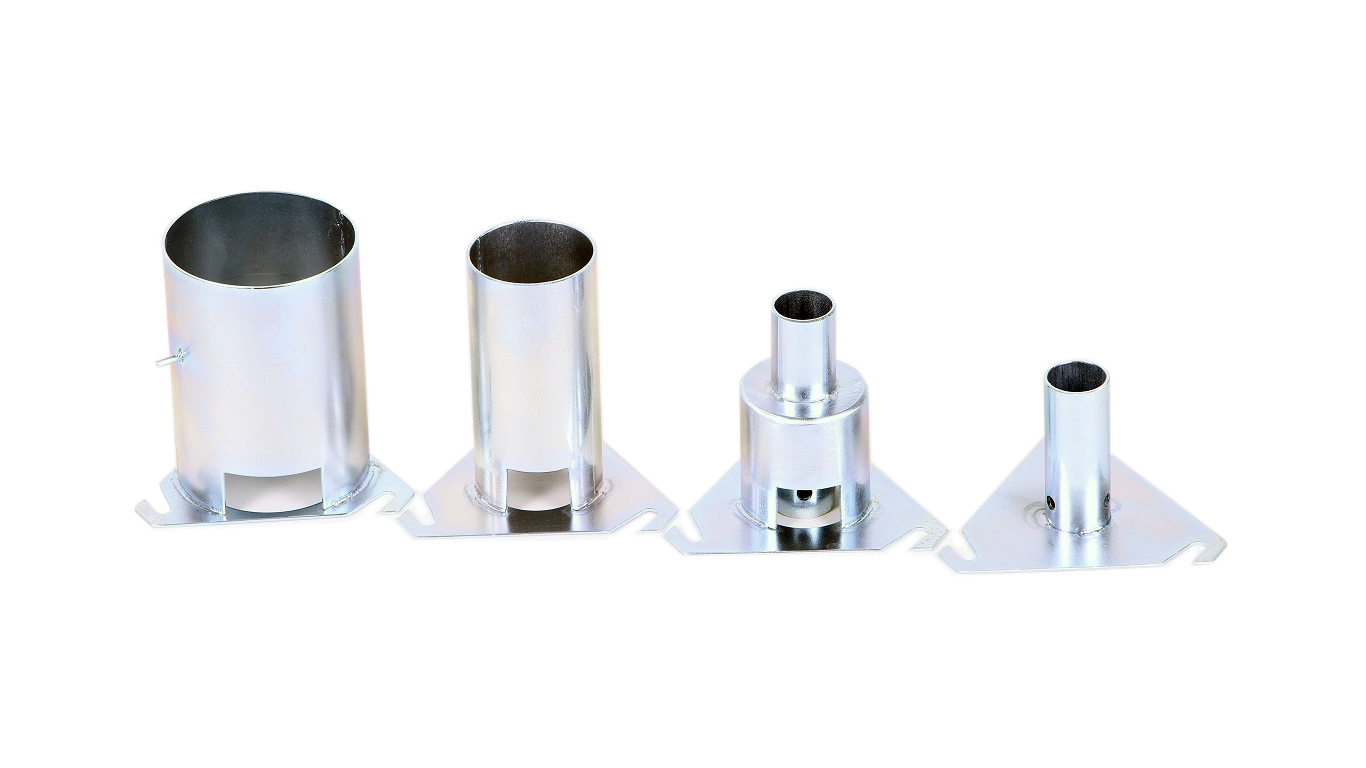

Smoke can be ducted at very low output, (as illustrated) to highlight for example laminar flow, or at high output, if smoke logging areas for the purpose of training or leak testing.

For larger volumes where dense smoke logging is required, we would normally recommend the use of fan-assisted distribution systems. These allow ducting runs of typically 30-40m.

This allows for several rooms or compartments to be smoke logged simultaneously if required, distributing the smoke typically through smooth bore PVCu pipework into the respective areas. Fan assistance can greatly improve the effectiveness of ducted systems.

Generally, a small amount of deposition should be expected in ducting systems as the smoke particles are being artificially restricted, and cannot separate and spread out as they would in free air. For best results, the ducting should be as short and straight as possible, with as smooth a bore as practical, so that frictional losses within the duct are kept to a minimum.

If you have an application that calls for the ducting of smoke then please contact us. We would be pleased to assist you in specifying the correct ducting and fan combination.

Demonstration Video

Require more information?

Please get in touch if you’d like to discuss any technical queries, or provide advice or simply require more information.